Tungsten carbide dies have become indispensable in the metal fastener mold industry, particularly in the production of bolts, studs, screws, and nuts. These dies are crafted using tungsten carbide — a hard, dense metal compound known for its exceptional mechanical properties. The application of tungsten carbide dies provides a range of significant benefits that enhance both the quality of the fasteners produced and the overall efficiency of manufacturing processes.

This article outlines the primary benefits of tungsten carbide dies in fastener production and explains why they are widely preferred in high-precision and high-volume industrial settings.

1. Exceptional Hardness and Wear Resistance

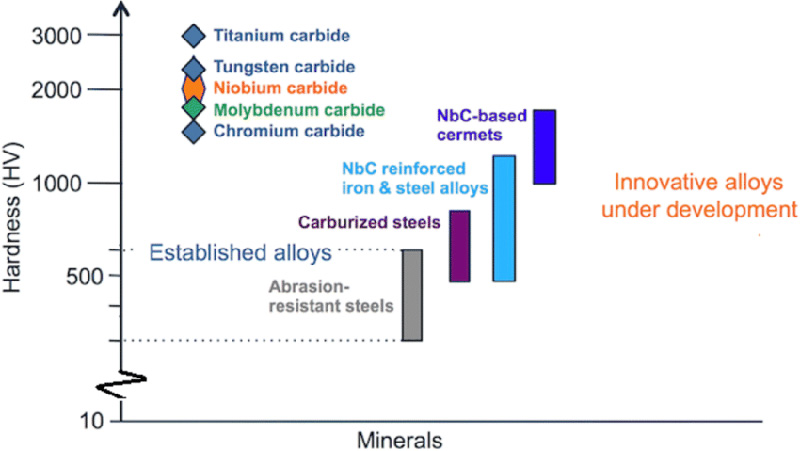

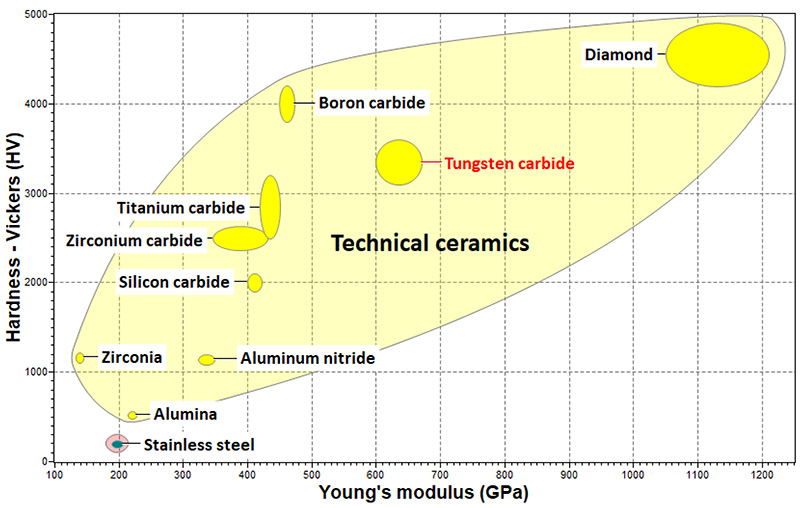

One of the most prominent advantages of tungsten carbide dies is their superior hardness. On the Mohs scale, tungsten carbide ranks around 9, making it one of the hardest materials next to diamond. This property translates into outstanding wear resistance, particularly during high-speed cold heading and forming operations where standard tool steels may rapidly degrade.

In fastener production, dies are subjected to enormous compressive forces and repeated impact. The durability of tungsten carbide ensures that the die retains its dimensional integrity over a long service life. This reduces tool wear and deformation, even when processing hard materials such as stainless steel, alloy steel, and titanium.

2. Extended Tool Life

The hardness and wear resistance of tungsten carbide directly contribute to an extended tool life. Compared with traditional steel dies, tungsten carbide dies can last up to 10 times longer, depending on the application and operating conditions. This longer lifespan translates into several practical benefits:

- Reduced downtime due to less frequent die changes.

- Lower tooling costs over time, despite a higher initial investment.

- Improved production consistency thanks to stable die performance over more parts.

The extended life of tungsten carbide dies is especially beneficial in high-volume manufacturing environments where tooling stability and longevity are crucial.

3. High Compressive Strength and Toughness

Tungsten carbide possesses high compressive strength, typically above 600,000 psi. This makes it capable of withstanding the intense forces generated during the cold heading, thread rolling, and extrusion processes common in fastener manufacturing.

Although tungsten carbide is generally more brittle than tool steels, modern binder technologies (using cobalt or nickel) and advanced sintering methods have significantly improved its toughness. This ensures that tungsten carbide dies can resist chipping and fracturing under intermittent loads, which are common in multi-station cold forming operations.

4. Precision and Dimensional Stability

In fastener manufacturing, maintaining tight dimensional tolerances is critical for quality control and downstream assembly performance. Tungsten carbide dies provide excellent dimensional stability, even under prolonged exposure to heat and pressure.

Thanks to its low thermal expansion and minimal wear, tungsten carbide ensures that the die cavity dimensions remain consistent across large production batches. This contributes to:

- Uniform thread profiles and head shapes.

- Minimal variation in fastener diameter or length.

- Reduced need for rework or sorting.

This precision is vital for industries such as automotive, aerospace, and construction, where fastener reliability and fit are non-negotiable.

5. Cost Efficiency in Mass Production

While tungsten carbide dies are more expensive upfront compared to standard tool steels, their extended life, reduced maintenance needs, and superior performance in high-speed machines make them highly cost-effective over time.

In fastener factories operating 24/7, die failure or frequent replacements can disrupt production flow and raise costs. By using tungsten carbide dies, manufacturers can maintain longer production runs with less intervention, translating into:

- Lower cost per part.

- Higher equipment utilization.

- Fewer line stoppages and increased output.

This makes them the die of choice for mass production lines, especially in the manufacture of high-performance or specialty fasteners.

6. Compatibility with Surface Treatments and Coatings

Tungsten carbide dies can be further enhanced with coatings such as titanium nitride (TiN), titanium carbonitride (TiCN), or diamond-like carbon (DLC). These coatings can reduce friction, improve lubricity, and enhance wear resistance even further.

In fastener forming, where galling or adhesion can occur, such surface treatments help prolong die life and ensure smooth metal flow, especially when forming aluminum, copper, or stainless steels. The ability to combine the base strength of tungsten carbide with advanced coatings makes it a highly versatile tooling option.

7. Environmental and Sustainability Benefits

From a sustainability perspective, longer-lasting tooling means fewer resources are consumed for replacement dies, and less scrap is generated due to tooling-induced defects. Additionally, improved tool life reduces the energy and labor required for frequent maintenance or adjustments.

Many manufacturers are moving toward “green production” practices, and using high-efficiency, long-life tungsten carbide tooling aligns with this trend by reducing the environmental footprint of the fastener manufacturing process.

Conclusion

Tungsten carbide dies offer a compelling combination of strength, wear resistance, precision, and cost-effectiveness that make them ideal for the demands of fastener production. While their initial cost is higher than that of conventional dies, their long-term benefits — including extended life, improved product quality, and lower total operating costs — far outweigh the investment.

For manufacturers aiming to achieve high throughput, consistent quality, and operational reliability in forming bolts, studs, screws, and nuts, tungsten carbide dies are not just an option — they are a strategic necessity.